1. Akufuneki kubekho i-skew kunye ne-swing xa i-sprocket ifakwe kwi-shaft. Kwindibano efanayo yokudluliselwa, ubuso bokuphela kwee-sprockets ezimbini kufuneka zibe kwindiza efanayo. Xa umgama ophakathi we-sprockets ungaphantsi kwe-0.5m, ukuphambuka okuvumelekileyo ngu-1mm; Xa umgama ophakathi we-sprocket ungaphezulu kwe-0.5m, ukuphambuka okuvumelekileyo ngu-2mm. Nangona kunjalo, akukho friction evunyelweyo kwicala lamazinyo e-sprocket. Ukuba amavili amabini ahamba kakhulu, kulula ukubangela ukuhlukana kwamakhonkco kunye nokukhawuleza ukunxiba. Nika ingqalelo ukujonga kwaye ulungelelanise i-offset xa utshintsha i-sprocket.

2. Ukuba iqinile kakhulu, ukusetyenziswa kwamandla kuya kwandiswa kwaye ukuthwala kuya kunxiba lula; ukuba ukhululekile kakhulu ikhonkco lokuphakamisa kulula ukutsiba kwaye unduluke. Ukuqiniswa kwekhonkco lokunyusa kukuba: phakamisa okanye ucinezele ukusuka phakathi kwekhonkco, umgama ophakathi kwee-sprockets ezimbini malunga ne-2% - 3%.

3. Esetyenzisiweyoikhonkco lokuphakamisaayinakuxutywa kunye namanye amatyathanga amatsha, kungenjalo kulula ukuvelisa impembelelo ekuhanjisweni kunye nokuqhawula ikhonkco.

4. Emva kokunxiba kakhului-sprocket, i-sprocket entsha kunye nekhonkco elitsha kufuneka itshintshwe ngexesha elifanayo ukuqinisekisa ukuba i-meshing ilungile. Akunakwenzeka ukutshintsha ikhonkco elitsha okanye isprocket ngokwahlukeneyo. Ngaphandle koko, iya kubangela i-meshing embi kwaye ikhawulezise ukunxitywa kwekhonkco elitsha okanye i-sprocket. Emva kokuba indawo yezinyo le-sprocket igqitywe kwinqanaba elithile, kufuneka liguqulwe ngexesha (libhekisela kwi-sprocket kunye nomhlaba olungelelaniswayo). Ukwandisa ixesha lokusetyenziswa.

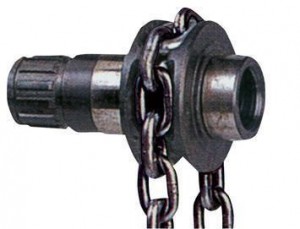

5. Ikhonkco entsha yokuphakamisa ide kakhulu okanye yoluliwe emva kokusetyenziswa, okunzima ukuyilungisa. Amakhonkco ekhonkco anokususwa ngokwemeko, kodwa inombolo yekhonkco yekhonkco kufuneka ilingane. Ikhonkco lekhonkco liya kudlula ngasemva kwekhonkco, iqhekeza lokutshixa liya kufakwa ngaphandle, kwaye ukuvuleka kweqhekeza lokutshixa kuya kuba kwicala elichaseneyo lokujikeleza.

6. Ikhonkco lokuphakamisa kufuneka lizaliswe ngeoli yokuthambisa ngexesha. Ioli yokuthambisa kufuneka ingene kwi-fit clearance phakathi kwe-roller kunye nomkhono wangaphakathi ukuze kuphuculwe iimeko zokusebenza kunye nokunciphisa ukunxiba.

Ixesha lokuposa: Jul-17-2021