I. Ukubaluleka kokuKhetha amatyathanga namatyathanga aLungileyo

Kwimizi-mveliso yesamente, izinyusi zamabhakethi zibalulekile ekuthuthweni kwezinto ezinzima, ezirhabaxa kakhulu ezifana neklinka, ilitye likalikalika, kunye nesamente ngokuthe nkqo.Ikhonkco elijikelezayo lamatyathanga kunye namakhamandelabathwale uxinzelelo olubalulekileyo lomatshini, ukwenza uyilo lwabo kunye nolawulo lomgangatho wemveliso luyimfuneko kwimpumelelo yokusebenza. Nasi isizathu sokuba ukukhetha amacandelo afanelekileyo kubalulekile kwaye i-SCIC ilungisa njani oku:

1. Umthamo wokuThwala umthwalo:Amatyathanga namakhamandelakufuneka imelane nemithwalo ephezulu yokuqina kunye neempembelelo zomothuko ezivela kwintshukumo eqhubekayo yamabhakethi. Amalungu angekho mgangathweni abeka esichengeni sokungaphumeleli ngequbuliso, okukhokelela ekuphelelweni kwexesha, iingozi zokhuseleko, kunye nolungiso olubiza imali eninzi. Ukubambelela kwe-SCIC kwimigangatho ye-DIN iqinisekisa ukuba iimveliso zethu ziyahlangabezana neemfuno zamandla afunekayo, njengamandla achaziweyo ophula angama-280–300 N/mm².

2. I-Resistance yokuGqoka: Ubume be-abrasive bezinto ze-samente zikhawuleza ukunxiba kumacandelo e-elevator. Amatyathanga aqiniswe yimeko (ukuya kuthi ga kwi-800 HV) kunye namatyathanga (ukuya kuthi ga kwi-600 HV) abonelela ngomphezulu oqinileyo wokuxhathisa i-abrasion, ngelixa ugcina ukuqina okungundoqo ukuthintela ukuqhekeka. Inkqubo echanekileyo ye-SCIC yokubeka i-carburizing ifikelela kwi-10% ye-carburizing eceliwe kunye ne-5-6% yobunzulu bobulukhuni obusebenzayo, iqinisekisa ukusebenza kwexesha elide.

3. Ukuthotyelwa kweMigangatho: Ukuthotyelwa kweDIN 764, DIN 766, DIN 745, kunye neDIN 5699 iqinisekisa ukubaamatyathanga namakhamandelaukuhlangabezana nemigangatho yoshishino yemilinganiselo, iipropathi zemathiriyeli, kunye nokuthembeka. Ubungcali be-SCIC ekuhlangabezaneni nale migangatho buqinisekisa umgangatho ongaguqukiyo olungiselelwe izicelo ezinzima.

4. Ukulawulwa koMgangatho weMveliso: Ukulawulwa komgangatho ongqongqo we-SCIC-ukusuka ekukhethweni kwezinto ukuya ekuhlolweni kokugqibela-kunciphisa iziphene kwaye kuqinisekiswe ukuchaneka komda, ubulukhuni kunye namandla. Esi sikhundla sinciphisa ukubakho kokusilela phantsi kweemeko ezinzima zeefektri zesamente.

Ukukhetha okulungileyoamatyathanga namakhamandelaibaluleke kakhulu ekusebenzeni kakuhle kunye nokhuseleko lwezinyusi zakho zamabhakethi. Kwi-SCIC, iimveliso zethu ziyilelwe kwaye zenziwa ukuhlangabezana nemigangatho engqongqo ye-DIN, ukuqinisekisa ukuba ziyakwazi ukumelana nemithwalo enzima kunye nezinto ezixutywayo eziqhelekileyo kwiifektri zesamente. Ngolawulo lwethu olungqongqo lwekhwalithi, unokuthembela ukuba amatyathanga kunye neentambo zethu ziya kubonelela ngokusebenza okuthembekileyo, ukunciphisa umngcipheko wokungaphumeleli okungalindelekanga kunye neendleko zokugcina.

II. Ukulinganisa Ukuqina kunye namandla Ngexesha Lokuvelisa

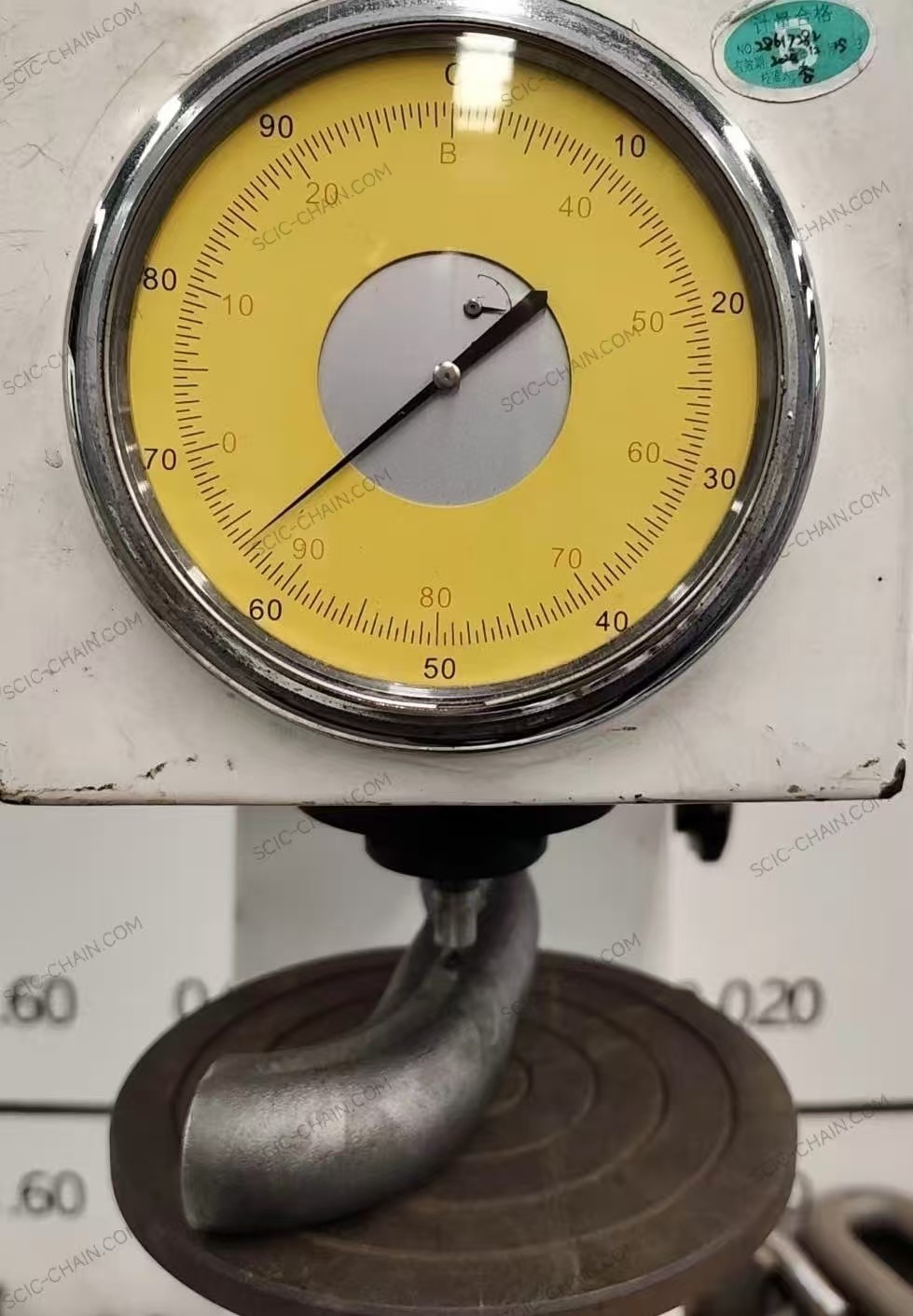

Ukuphumeza ubulukhuni obuxeliweyo bomphezulu womxhasi (800 HV kumatyathanga, 600 HV ngamakhamandela), ubungqingqwa be-carburizing (10% yedayamitha yekhonkco), ubunzulu obusebenzayo bokuqina (550 HV ku-5–6% yedayamitha), kunye nokwaphuka kwamandla (280–300 N/mm²) kufuna ulungelelwaniso olucokisekileyo phakathi kokuqina namandla. Nantsi indlela i-SCIC ikufeza ngayo oku ngokukhethwa kwezinto, unyango lobushushu, kunye nokungcwatywa kwe-carburizing:

IiNkqubo zoMveliso eziPhambili

1. Ukukhethwa kwezinto:I-high-carbon okanye i-alloy steels ikhethwa ngenxa yokukwazi ukuphendula kwi-carburizing kunye nokucima, ukubonelela kokubili ubunzima bomhlaba kunye nokuqina okungundoqo.

2. Ukungcwatywa:I-Carburizing isasaza ikhabhoni kumphezulu wentsimbi ukunyusa ubulukhuni. Kwikhonkco lekhonkco elinobubanzi obuyi-20 mm;Ubunzulu beCarburizing: 10% ye-20 mm = 2 mm;Ubunzulu boBulukhuni obusebenzayo: 5-6% ye-20 mm = 1-1.2 mm kwi-550 HV;Oku kudala umgangatho oqinileyo, ongagugiyo ngelixa ugcina i-ductile core ukufunxa imithwalo eguqukayo.

3. Unyango lobushushu:Ukucima: Emva kwe-carburizing, amacandelo ayacinywa ukuze atshixe ngobulukhuni bomphezulu (800 HV ngamatyathanga, 600 HV ngamakhamandela);Ukufudumeza: Ubushushu obulawulwayo (umzekelo, kuma-200–250°C) kulungelelanisa iimpawu zondoqo, ukuqinisekisa ukomelela kunye namandla okuqhawula afunekayo angama-280–300 N/mm². Ukucaphuka ngokugqithiseleyo kunciphisa ubulukhuni, ngelixa ubushushu obuphantsi bubeka umngcipheko wokuba brittleness.

4. UMthetho woLungelelaniso: Ukuqina: Ubulukhuni obuphezulu bomphezulu buchasa ukunxiba kwizinto ezirhawukayo;Amandla: Ukuqina okungundoqo kuthintela iifractures ezinqabileyo phantsi kwemithwalo enzima.I-SCIC ilawula ubunzulu be-carburizing kunye neeparamitha zobushushu ukunqanda ubuqhophololo obugqithileyo ngelixa udibana neenkcukacha zabathengi.

(amakhonkco amakhonkco anobunzima obuphezulu bomphezulu we-carburized)

(amakhonkco amakhonkco anobunzima obuphezulu be-carburized surface, emva kokuqhawula uvavanyo lwamandla)

Inkqubo yethu yokuvelisa ilawulwa ngononophelo ukufezekisa ukulingana okugqibeleleyo phakathi kobunzima kunye namandla. Ngokusebenzisa i-carburizing echanekileyo kunye nonyango lobushushu, siqinisekisa ukuba wethuamatyathanga namakhamandelayiba nomphezulu oqinileyo, ongagugiyo ngelixa ugcina isiseko esiqinileyo sokuphatha imithwalo eguquguqukayo kwimisebenzi yakho. Le bhalansi ibalulekile ekwandiseni ubomi kunye nokuthembeka kwesixhobo.

III. Ukuqinisekisa uBomi obuBomi ngokuSebenza kunye noLondolozo

Nokuba kunyeamatyathanga namakhamandela akumgangatho ophezulu, ukusebenza ngendlela eyiyo kunye nokugcinwa kwezinto kubalulekile ukuze kwandiswe ixesha lokuphila kwizinyusi zeebhakethi zasefektri yesamente. I-SCIC ibonelela ngezi zikhokelo zilandelayo kubathengi:

IziKhokelo zokuLondoloza

1. Uhlolo lwarhoqo:Khangelaamatyathanga namakhamandelakwiimpawu zokunxiba, ezinje ngobude (umzekelo, >2–3% yobude bokuqala), ukonakala, okanye ukuqhekeka komphezulu. Ukufunyaniswa kwangoko kuthintela ukusilela.

2. Ukuthambisa:Faka ubushushu obuphezulu, izithambisi ezinobunzima bokunciphisa ukukhuhlana kunye nokuguga. Lubricate rhoqo iiyure zokusebenza eziyi-100–200, kuxhomekeke kwiimeko.

3. UkuJonga iTension:Gcina uxinezeleko lwetyathanga olulolona luphezulu ukunqanda ukuyekelela ngokugqithisileyo (okubangela ukuxhuzula) okanye ukuqinisa kakhulu (ukunxiba okunyukayo). Lungisa ngokweenkcukacha zeSCIC.

4. Ukutshintshwa kwangexesha:Faka izinto ezigugileyo okanye ezonakeleyo ngoko nangoko ukuze uthintele ukungaphumeleli kwe-cascading. Umzekelo, ikhonkco eligogekileyo kufuneka litshintshwe ngokukhawuleza.

5. IiNdlela eziPhambili zokuSebenza:Sebenza ngaphakathi kwemida yoyilo (umzekelo, kunqande ukugcwala okungaphaya kwama-280–300 N/mm² ukophula amandla omthamo) ukunciphisa uxinzelelo.

Ukwandisa ubude bobomi bamatyathanga namatyathanga akho, landela ezi ndlela zokuziqhelanisa: jonga rhoqo ukunxiba, uqinisekise ukuthanjiswa okufanelekileyo, jonga ukuxinana kwamatsheyini, kwaye ubuyisele izinto ezonakeleyo ngokukhawuleza. Ngokuthobela ezi zikhokelo kunye nokusebenza ngaphakathi kwemida yoyilo, unokwandisa kakhulu ukuthembeka kunye nokusebenza kakuhle kwezinyusi zakho zebhakethi.

I-Case Study: Impembelelo yeHlabathi yokwenyani

Imeko:

Umzi-mveliso wesamente uye wajongana nokusilela rhoqo kwekhonkco elingqukuva, kunye nexesha lokuphumla leeyure ezili-10 ngenyanga ngenxa yamatyathanga anobulukhuni be-HV engama-600 kunye nobunzulu obunzulu be-carburizing. Oku kubangele iindleko eziphezulu zokulungisa kunye nokulahleka kwemveliso.

Isisombululo:

Umzi-mveliso wamkela i-SCIC's case-hardened link chain chain:

-Iiparamitha: 30mm ubukhulu, 800 HV ubulukhuni bomphezulu, 3mm ubunzulu be-carburizing, 1.8mm ukuqina okusebenzayo kwi-550 HV, 290 N/mm² amandla okuqhawuka.

- Ugcino: Ukuhlolwa kabini ngeveki, ukuthanjiswa rhoqo kwiiyure ezili-150, kunye nohlengahlengiso loxinzelelo.

(amakhonkco ekhonkco kunye nobunzulu obuphuculweyo be-carburizing ukuya kwi-10% yekhonkco ye-diameter)

IV. Iziphumo

1. Ixesha lokuphumla: Ukunciphisa i-80% (ukuya kwiiyure ze-2 / inyanga).

2. Ubomi: Amatyathanga ahlala iinyanga ezili-18 (vs. 6 iinyanga ngaphambili).

3. Ugcino lweendleko: Iindleko zokugcina zehle ngama-50% ngonyaka.

Oku kubonisa indlela amacandelo e-SCIC akumgangatho ophezulu kunye nesikhokelo sogcino ezizisa ngayo iinzuzo ezibonakalayo.

V. Isiphelo

1. Ukukhetha aMalunga aLungileyo:I-SCIC's DIN-ethobela amatyathanga namatyathanga, exhaswa yi-design ephezulu kunye nokulawula umgangatho, qinisekisa ukhuseleko kunye nokusebenza kakuhle kwii-elevators zebhakethi ze-sement factory.

2. Ukulinganisa Ukuqina kunye namandla: Iinkqubo zethu zokuvelisa ezichanekileyo zihlangabezana neenkcukacha zabathengi, ukuhambisa ukuxhathisa ukunxiba kunye nomthamo wokuthwala umthwalo.

3. Ukwandisa ixesha loBomi: Isikhokelo solondolozo esisebenzayo siqinisekisa ukuthembeka kwexesha elide.

Ngokubambisana ne-SCIC, abathengi bafumana ukufikelela kwiintambo ezenziwe ngobuchule kunye neentambo, ezilungiselelwe iimfuno zabo, kunye nokuxhaswa ngezicwangciso eziqinisekisiweyo zokuphucula ukusebenza kunye nokunciphisa iindleko.

Ixesha lokuposa: Apr-21-2025