Ukusika ibha → ukugoba okubandayo → ukudibanisa → ukuwelda → ulungelelwaniso lokuqala → unyango lobushushu → ulungelelwaniso lwesibini (ubungqina) → ukuhlolwa. I-Welding kunye nonyango lokufudumala ziinkqubo eziphambili kwimveliso yemigodi yentsimbi ejikelezayo yentsimbi, echaphazela ngokuthe ngqo umgangatho wemveliso. Imilinganiselo ye-welding yenzululwazi inokuphucula isivuno kunye nokunciphisa iindleko zemveliso; Inkqubo yonyango efanelekileyo yokushisa inokunika umdlalo opheleleyo kwiipropati eziphathekayo kunye nokuphucula umgangatho wemveliso.

Ukuze kuqinisekiswe umgangatho we-welding we-mining round link steel chain, i-arc manual kunye ne-resistance butt welding iye yapheliswa. I-flash butt welding isetyenziswa kakhulu ngenxa yomgangatho wayo ophezulu wokuzisebenzela, ubungakanani bomsebenzi ophantsi, umgangatho wemveliso ozinzile kunye nezinye iingenelo ezibalaseleyo.

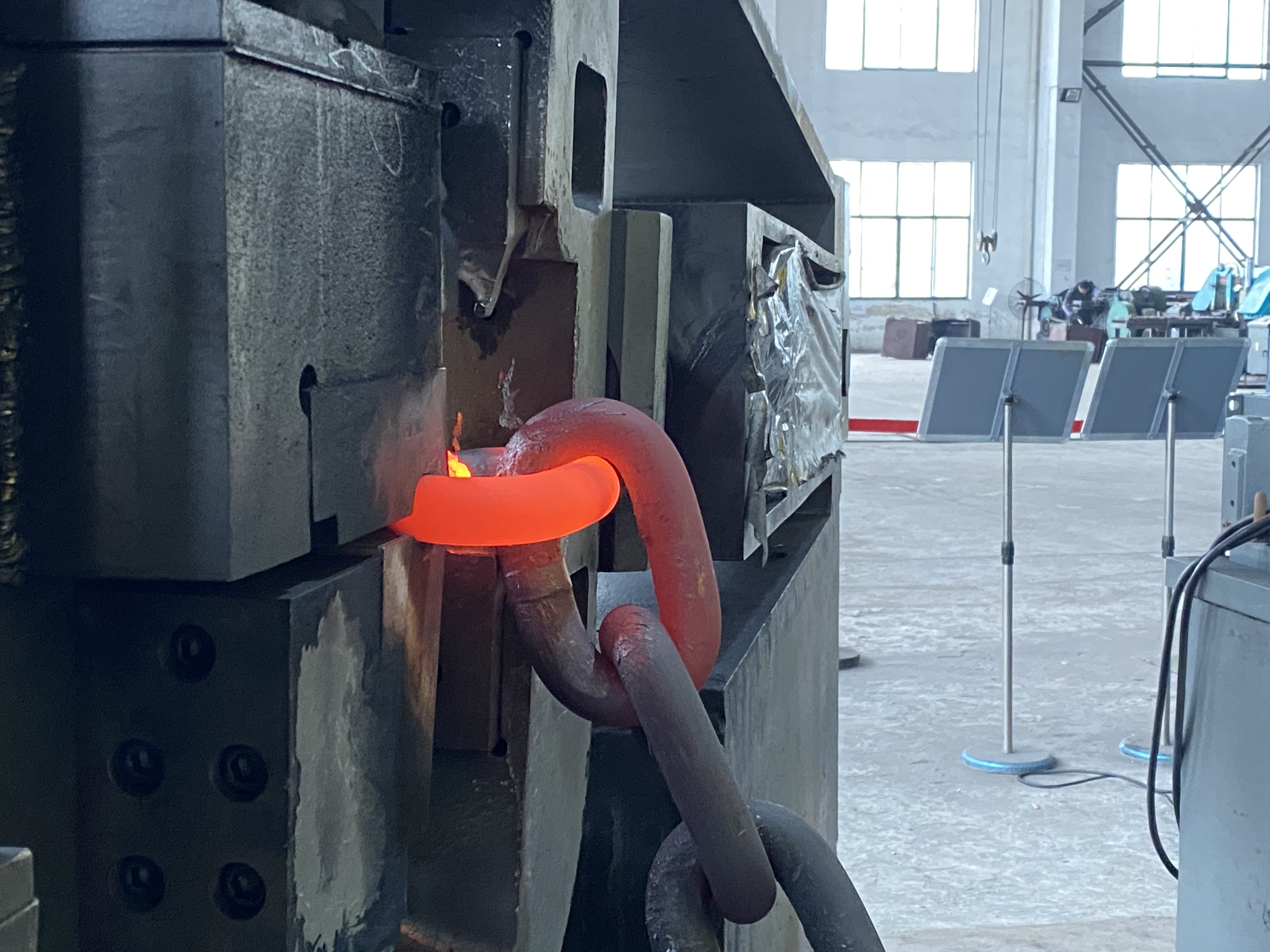

Okwangoku, ukufudumeza okuphakathi kokufudumeza okuqhubekayo kunye nendlela yokufudumeza isetyenziswa ngokubanzi kunyango lobushushu lwekhonkco lentsimbi yekhonkco elijikelezayo. Undoqo wokufudumeza okuphakathi kwamaza aphakathi kukuba ubume bemolekyuli bento bushukunyiswa phantsi kommandla we-electromagnetic, kwaye imolekyuli ifumana amandla kwaye iyangqubana ukwenza ubushushu. Xa i-medium frequency induction heat treatment iqhutywa, i-inductor idityaniswe ne-medium frequency alternating current ye-frequency ethile, kwaye i-workpiece ihamba ngesantya esifanayo kwi-sensor, ukwenzela ukuba i-induction yangoku kunye ne-frequency efanayo kunye necala elichaseneyo liya kuveliswa kwindawo yokusebenza, eya kutshintsha amandla ombane abe ngamandla obushushu, kwaye i-workpiece iya kufudunyezwa kwiqondo lokushisa elifunekayo ngokucima ixesha elifutshane kunye nokucima.

Ukufudumeza okuphakathi kwe-frequency induction kunezibonelelo zesantya sokufudumeza ngokukhawuleza, i-oxidation encinci, isakhiwo sokucima kakuhle kunye nobungakanani bengqolowa ye-austenite emva kokucima, okuphucula amandla kunye nokuqina kwekhonkco lekhonkco. Ngelo xesha, nayo ineenzuzo zokucoceka, ukulungiswa okulula kunye nokusebenza kakuhle kwemveliso. Kwinqanaba lokuthomalalisa, ubushushu obuphezulu bobushushu kwindawo ye-welding yekhonkco inokuphelisa ukucima uxinzelelo lwangaphakathi ngexesha elifutshane, elinempembelelo ebaluleke kakhulu ekuphuculeni iplastikhi kunye nokuqina kwendawo ye-welding yekhonkco kunye nokulibazisa ukuqaliswa kunye nophuhliso lweentanda. Ubushushu bokufudumala phezulu kwegxalaba buphantsi, kwaye ukuqina kuphezulu emva kokufudumala, okulungele ukunxitywa kwekhonkco lekhonkco kwinkqubo yokusebenza kunye nokuchasene ne-hinge phakathi kweekhonkco zekhonkco kunye ne-sprocket meshing.

Ixesha lokuposa: May-10-2021